The modern food industry requires different dairy ingredients as ingredients or bases for processed products, and a market for using milk protein powders as ingredients for food processing has been formed. The production cost of milk protein powder is lower than other animal proteins, and it also has good functional properties in food.

Milk protein powder is mainly composed of two types of proteins, namely casein and whey protein, of which casein accounts for about 80% of the total protein, and whey protein accounts for about 20% of the total protein. Casein products have good functionality and are suitable as stabilizers, thickeners and gelling agents. Since casein has relatively concentrated hydrophilic and hydrophobic regions, it has good foaming and emulsifying properties.

Casein and sodium caseinate also have excellent functionality in other respects. The application of casein in meat products can effectively improve the quality of meat products, improve the water retention and fat retention capacity of meat products. Additional functions include protein fortification in baked goods, thickening in margarine or coffee mates, and production of simulated cheeses and beverages.

The preparation methods of milk protein powder include high-speed centrifugation, salting out, organic solvent ethanol precipitation, cryoprecipitation, membrane technology, electroosmosis, etc. Compared to the traditional casein production method, acid precipitation, these methods have limitations, especially the production cost. However, spray drying has short time consumption, low energy consumption, little impact on product quality, and is suitable for continuous automated production with large production capacity. Therefore, spray drying is the best choice for preparing milk protein powder and is suitable for industrial production.

In order to be able to produce high-quality, high-agglomeration, easy-to-pack products. After continuous exploration, FBL engineers specially designed FBL-LPG high speed centrifugal spray dryer with new technology, which can successfully dry viscous, hygroscopic, thermoplastic and slow-crystallizing products into free-flowing agglomerated powder . Compared with the traditional dryer, the spray dryer with the new technology has a lower drying temperature, and the residence time of the product in the dryer is longer during the whole drying process, and the quality of the product is not affected.

Small spray dryer

Features of the new dairy spray dryer:

1. The new type of dairy spray dryer adopts a large color touch screen operation, a combination of automatic control and manual control, and comes with a memory function.

2. Fully automatic control: One-button start-up, after setting the spray process parameters, the temperature reaches the predetermined temperature, the peristaltic pump starts automatically, the running animation is displayed on the touch screen, and the running process is clearly displayed.

3. Shutdown protection function: After pressing the stop button, the machine will stop running immediately except for the fan, to ensure that the heating part of the equipment will not be burned out due to misoperation.

4. In the design of drying temperature control, the real-time PID constant temperature control technology is used to make the temperature control in the whole temperature area accurate, and the heating temperature control accuracy is ±1℃.

5. The spraying, drying and collection system is made of transparent high-quality borosilicate heat-resistant glass material, so that the spray-drying process can be carried out in a pollution-free environment, and the entire spray-drying experiment process can be directly observed, which can be found and solved in time question.

6. The new type of dairy spray dryer has a built-in imported oil-free air compressor. The particle size of the powder is normally distributed, the fluidity is very good, and the noise is very low.

7. The atomization structure of the two-fluid spray, the whole machine is made of high-quality stainless steel material, the design is compact, no auxiliary equipment is required, and it is easy to use.

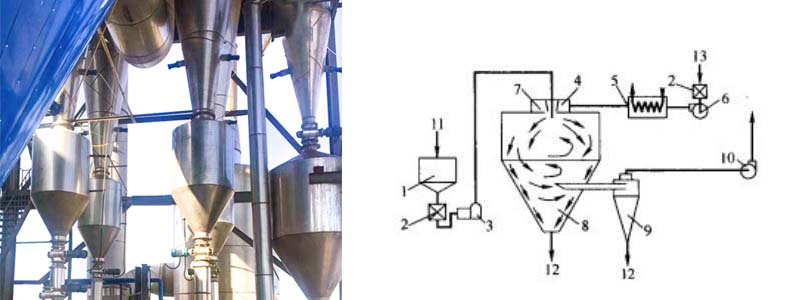

The working process of the new type of dairy spray dryer:

Material preparation->Atomization->Drying->Separation->Cooling and packaging

How does a spray dryer work?

1. The fresh air from the outside enters the air heater through the air filter and blower, so that the air temperature is raised to about 160 ℃ and sent to the drying room.

2. Before entering the drying room, the hot air first passes through the air distribution plate to make the hot air evenly distributed to ensure the drying effect.

3. The material liquid to be dried is sterilized into the material tank, and then pumped to the atomizer by pressure pump. The material liquid is sprayed out in the form of a mist and mixed with hot air. The material particles absorb heat, and the water evaporates instantly to form The powder falls downward and undergoes a period of constant drying to further evaporate the water.

4. The dried material is separated by the separator, the waste air is discharged by the exhaust fan, and the dried fine powder products are continuously discharged by the unloader.

Extra large spray dryer for mass production

Advantages of the new dairy spray dryer:

1. Unlike other traditional spray dryers, which need to recover fine powder, the agglomerated powder produced by the new technology spray tower does not need to recover fine powder.

2. The exhaust gas can meet the emission standard without installing an air purification device.

3. Simple cleaning and inspection, short production downtime.

4. The exhaust temperature is much lower than other forms of dryers, which can achieve efficient heat utilization.

5. The surface area of the droplet group is larger, and the drying time required for the material is shorter.

6. In the high temperature airflow, the temperature of the material wetted on the surface does not exceed the wet bulb temperature of the drying medium, and the final product temperature is not high due to rapid drying. Therefore, spray dryers are especially suitable for heat-sensitive materials.

7. According to the flexibility of spray dryer operation, it can meet the quality indicators of various products, such as particle size distribution, product shape, product properties, product color, Aroma, taste, biological activity and moisture content of the final product.

8. Simplify the technological process. The solution can be directly made into a powder product in the drying tower. In addition, spray drying is easy to achieve mechanization and automation, reducing dust flying.

The new type of dairy spray dryer produced by FBL has stable performance and easy operation. In addition, we also have other drying equipment such as vacuum drying oven, blast drying oven, freeze dryer and so on. 13 years of production and export experience and a series of ISO9001 and CE certificates, with warehouses in the United States, Spain and Thailand.

If you want to know about our products, or want to buy our equipment, please feel free to contact us, FBL will offer you the best price on new type of dairy spray dryer.