As industrial hemp has gradually become a capital market outlet, the value of industrial hemp extract - CBD has been rapidly tapped. Today we will discuss the extraction of CBD through distillation equipment. At present, the distillation equipment that can extract cannabis cbd produced by our company includes closed-loop extraction, essential oil extraction, rotary evaporator, falling film evaporator, molecular distillation, short-path distillation, solvent recovery machine and supercritical extraction equipment.

Closed loop extraction:

Closed-loop extraction is used to extract solvent from solid matter. Characterized by the separation of air from the solvent during extraction, it minimizes the risk of explosion and provides a safe method of working with flammable solvents. Closed-loop extraction is often used to extract cbd in many places and is the preferred cannabis cbd extraction equipment

There are five types of cbd closed loop extraction equipment: 1lb, 2lb, 5lb, 10lb, 80lb

Essential Oil Extraction:

Essential oil extraction uses the solvency of the solvent to extract the essence of the plant, and then uses the vacuum distillation method to separate the chemical solvent to obtain the essential oil. Trim each cannabis flower leaf and divide the larger buds into smaller sections to extract the purest CBD oil from the cannabis flower through an essential oil extractor.

The main models are: TQ-10L, TQ-20L, TQ-50L, TQ-100L, TQ-200L and TQ-500L.

The oil-water separator is made of high borosilicate glass and SUS304 stainless steel

·Control system adopts Ruitai control system. Higher degree of automation, more precise temperature control

·The whole machine is made of 0CR18NI9TI and high-quality SS304

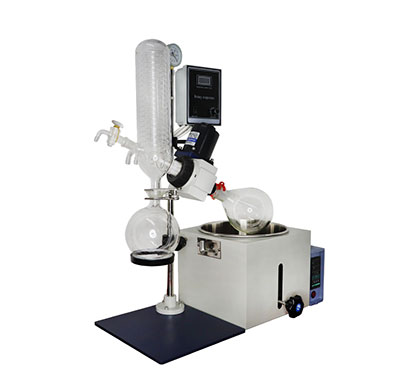

Rotary evaporator:

The rotary evaporator is an experimental instrument commonly used in chemical laboratories, which is used for the concentration of the extract and the distillation of the receiver during chromatographic separation. It is especially suitable for the concentration and purification of biological products that are easily decomposed and denatured at high temperature, such as cannabis cbd extraction. A rotary evaporator quickly and gently distills cannabis leaves to obtain cbd.

RE Series Small Capacity Rotary Evaporation Models: RE-201D, RE-301, RE-501, RE-5299

RE series small capacity automatic lift rotary steamer Model: RE-2000A, RE-2000B, RE-2000E

RE Series Large Capacity Rotary Evaporation Models: RE-1002, RE-2002, RE-5002

RE series large capacity automatic lift rotary steamer Model: RE-5002B, RE-2002B

RE series large-capacity explosion-proof rotary steamer Models: EXRE-1002, EXRE-2002, EXRE-5002

R series automatic lift rotary evaporator Model: R-1005, R-1010, R-1020, R-1050

·International advanced EL airtight system

Mechanical parts are made of stainless steel and aluminum alloy die-casting

·Double-layer condenser, the recovery rate is over 95%

Glass parts are made of borosilicate glass

·Built-in transmission system, frequency conversion speed regulation, stable and reliable speed

·The water bath adopts intelligent PID temperature controller, which can be lifted up and down

Falling film evaporator:

Falling film evaporator is also a kind of cbd oil extraction equipment, falling film evaporator has the characteristics of low temperature evaporation. Since the inside of the falling film evaporator can maintain a high degree of vacuum, the boiling point of the material to be treated will be greatly reduced. The material evaporates at low temperature and the heating time is short, which can keep the original flavor of the material to the greatest extent. Because the material evaporates into a film in each tube, the heating time of the material liquid is very short, so it is very beneficial to the evaporation and concentration of cannabis leaves, and the components of cannabis are largely preserved;

There are currently five types of falling film evaporators: KDJM-50, KDJM-200, KDJM-300, KDJM-600, KDJM-1000.

Evaporator: tube heat exchanger.

Separator: It is a tank with a single-layer structure. The upper secondary steam interface is communicated with the condenser, and the lower interface is communicated with the evaporator.

·Preheater: plate type/tube type.

·Condenser: The secondary steam is condensed for recycling.

·Condensate tank: single-layer structure tank, the tank body is equipped with a liquid level switch to control the liquid level.

·Heating chamber, the heating chamber is a tube-type scaling, the liquid material passes through the tube, and the material is heated, evaporated and vaporized.

Molecular Distillation:

Molecular distillation is a special liquid-liquid separation technology, which is different from the traditional distillation which relies on the separation principle of boiling point difference, but relies on the difference of the mean free path of molecular motion of different substances to achieve separation. It is characterized by low operating temperature, high vacuum degree, short heating time and high separation efficiency, and is especially suitable for the separation of high boiling point, heat sensitive and easily oxidizable substances.

Molecular distillation is one of the main distillation products of our company. At present, we have six models: YMD-060, YMD-80, YMD-100, YMD-150, YMD-200, YMD-230.

· High vacuum degree of distillation

· Short heating time

· Higher degree of separation

· Non-toxic, harmless, pollution-free, and residue-free, high purity and safe products can be obtained.

· The product consumes less energy, the internal pressure of molecular distillation is extremely low, and the internal resistance is much smaller than that of conventional distillation, so energy consumption can be greatly saved.

Short path distillation:

The working principle of short-path distillation is that the driving force of the steam flow is the pressure difference between the boiling film and the condensing surface, and a small pressure drop will cause the flow of steam. Under the premise of being non-toxic, non-polluting and non-residue, the short-path distillation technology can accurately separate the addictive component tetrahydrocannabinol (THC) in cannabis, while retaining the functional component of cannabis to the greatest extent. Phenol (CBD) and other cannabinoids, terpenes, flavonoids and other beneficial substances to the human body.

There are mainly the following types of short-path distillation units:

ZNCL-SPD-2L, ZNCL-SPD-5L, ZNCL-SPD-10L, ZNCL-SPD-20L

ZKCL-SPD-2L, ZKCL-SPD-5L, ZKCL-SPD-10L, ZKCL-SPD-20L (with custom thermal cover)

There are three supporting facilities for short-path distillation, namely: desktop circulating water vacuum pump, rotary vane vacuum pump and low temperature cooling liquid circulating pump.

· The product is made of high quality borosilicate glass.

· All metal parts are made of 304 stainless steel with good chemical resistance.

Is a physical separation process that keeps materials in their natural state, free from contamination.

· The heating time is very short, and it can be completed in tens of seconds. Low-carbon and environmentally friendly, it helps to maintain material activity.

· Flexible choice of vacuum pump and heater/cooler.

Solvent recovery machine

The solvent recovery machine is to process the used solvent, purify it into a clean, transparent and impurity-free solvent, and then recycle it into production. At the same time, the solvent recovery machine can be used with the evaporator to extract CBD. Taking industrial hemp as raw material, ethanol and water as solvent, through extraction and water extraction, a filtrate containing raw material components is obtained; the obtained filtrate is subjected to solvent recovery by an evaporator to obtain an extract, and the extract is distilled to obtain a cannabidiol enrichment ; and then use column chromatography to separate and purify the cannabidiol in the cannabidiol enrichment.

There are eight models of solvent recovery equipment: SR-20Ex, SR-40Ex, SR-60Ex, SR-80Ex, SR-100Ex, SR-125Ex, SR-250Ex, SR-450Ex,

The composition of the solvent recovery machine:

· Electric control box

· Drum tank

· Condensing pipe

· Condensing system

· Heating system

· Safety relief system

· Safe dumping system.

Supercritical extraction equipment:

Supercritical fluid extraction is a technology that uses supercritical fluid as an extractant to separate an extract from a mixture matrix.

It is also a cbd oil extraction equipment. Supercritical fluid extraction cbd is to first make cannabis flowers and leaves into powder, perform supercritical carbon dioxide extraction on the powder, and obtain liquid and residue after extraction; The solvent is recovered. When supercritical carbon dioxide is used to extract cannabis oil from cannabis, the extraction rate of cannabidiol can reach up to 90%, and the purity is above 20%.

There are currently four types of supercritical extractors, namely: SFE-5L, SFE-10L, SFE-25L, SFE-50L.

· CO2 is inexpensive, non-flammable, non-explosive, and sterilizing

· Gentle handling of heat-sensitive materials.

· The product and residues are free of solvents.

· Produce pure extract with few process steps

CO2 is recycled in plants, which is harmless to physiology and will not cause environmental problems such as some traditional solvents