A vacuum pump is a common laboratory instrument used to extract air and provide a vacuum environment. At present, there are three types of vacuum pumps commonly used in laboratories: circulating water vacuum pumps, diaphragm vacuum pumps and rotary vane vacuum pumps. The working principles of the three are different, and the scope of application is also different. This article mainly talks about the situation of rotary vane vacuum pump.Get Latest Price

This article introduces the rotary vane vacuum pump from the following aspects:

1. How the rotary vane vacuum pump operates?

2. How does the rotary vane vacuum pump work?

3. Rotary vane vacuum pump structure

4. Scope of application of rotary vane vacuum pump

5. How to maintain the rotary vane vacuum pump?

Rotary Vane Vacuum Pump Operation Method

1. Check the oil level, and it is advisable to fill the oil to the center of the oil mark when the pump is stopped. If it is too low, the exhaust valve cannot seal the oil and affect the vacuum degree. If it is too high, it may cause fuel injection when starting from the atmosphere. It is normal for the oil level to rise during operation. The oil adopts the specified grade of clean vacuum pump oil, which is added from the oil injection hole. After refueling, the screw plug should be screwed on. The oil should be filtered to prevent debris from entering and blocking the oil holes.

2. Connect the three-phase power cord according to the regulations. The three-phase motor should pay attention to the direction of rotation of the motor and the direction of the arrow on the pump bracket. The single-phase motor can be directly plugged into the power socket, and then start to work normally.

3. Check the connecting pipeline. The connecting pipeline with the pump inlet nozzle should not be too long. Be sure to check that the external connecting pipeline, joint and container of the vacuum pump cannot leak and must be sealed. Otherwise, the ultimate vacuum and the service life of the vacuum pump will be affected.

4. Check the working environment, the working environment of the rotary vane vacuum pump: the temperature is within the range of 5 ℃ ~ 40 ℃, the relative humidity is not more than 85%, and the air inlet pressure is 1.3*103 Pa. All vacuum pumps with pumping speed above 0.5 liters/second are equipped with gas ballast valves. If the relative humidity is high, the gas ballast valve can be opened for purification, and a small amount of water vapor can be removed without polluting the pump oil. Thereby improving the performance of the pump.

5. If the relative humidity is high, or the pumped gas contains a lot of condensable steam, after connecting the pumped container, the gas ballast valve should be opened, and the gas ballast valve should be closed after 20-40 minutes of movement. Before stopping the pump, the gas ballast valve can be opened for 30 minutes without load to prolong the life of the pump oil.

6. The self-priming oil-inlet vacuum pump should operate when the air inlet pressure is 10OKpa-6Kpa, and it should not exceed 3 minutes.

7. One of the following situations cannot be used:

(1) Can not suck gas containing particles, dust or colloidal, watery, liquid and corrosive substances.

(2) Do not pump explosive gas or gas with high oxygen content. In this environment, it is more appropriate to use the explosion-proof vacuum pump produced by our company.

(3) The container that cannot be leaked in the system and the matching of the vacuum pump is too large, and it will work under long-term pumping.

(4) Can not be used as air pump, compression pump, etc.

Working Principle of Rotary Vane Vacuum Pump

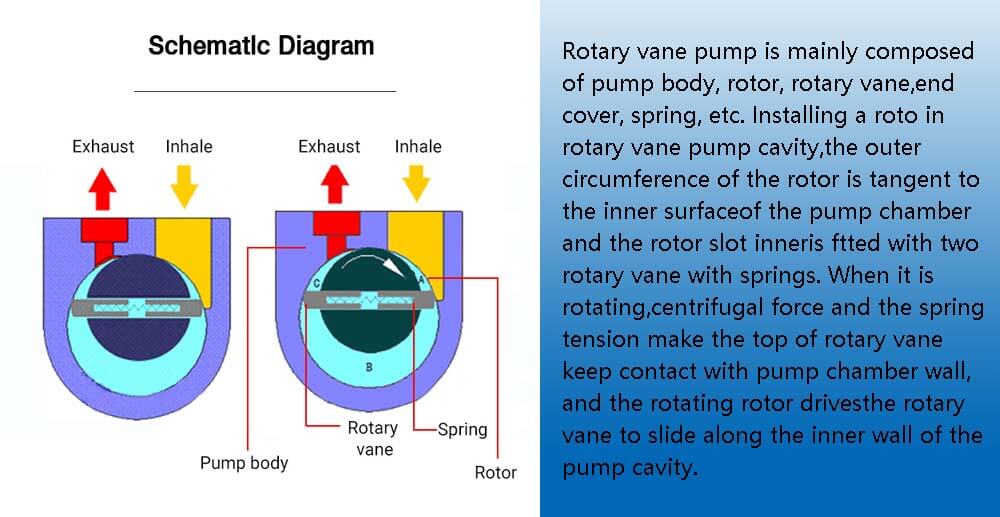

The rotary vane vacuum pump is an oil-sealed mechanical vacuum pump. Its working pressure range is 101325~1.33×10-2 (Pa), which belongs to low vacuum pump. Rotary vane vacuum pump is mainly composed of pump body, rotor, rotary vane, end cover, spring, etc. A rotor is eccentrically installed in the cavity of the rotary vane pump, the outer circle of the rotor is tangent to the inner surface of the pump cavity (there is a small gap between the two), and two rotary vanes with springs are installed in the rotor groove. During rotation, the top of the rotary vane is kept in contact with the inner wall of the pump chamber by centrifugal force and the tension of the spring, and the rotor rotates to drive the rotary vane to slide along the inner wall of the pump chamber. The purpose of continuous pumping is achieved by the continuous operation of the pump. The rotary vane vacuum pump needs to add vacuum pump oil and is heavy, but it has the advantage of a relatively large pumping rate.

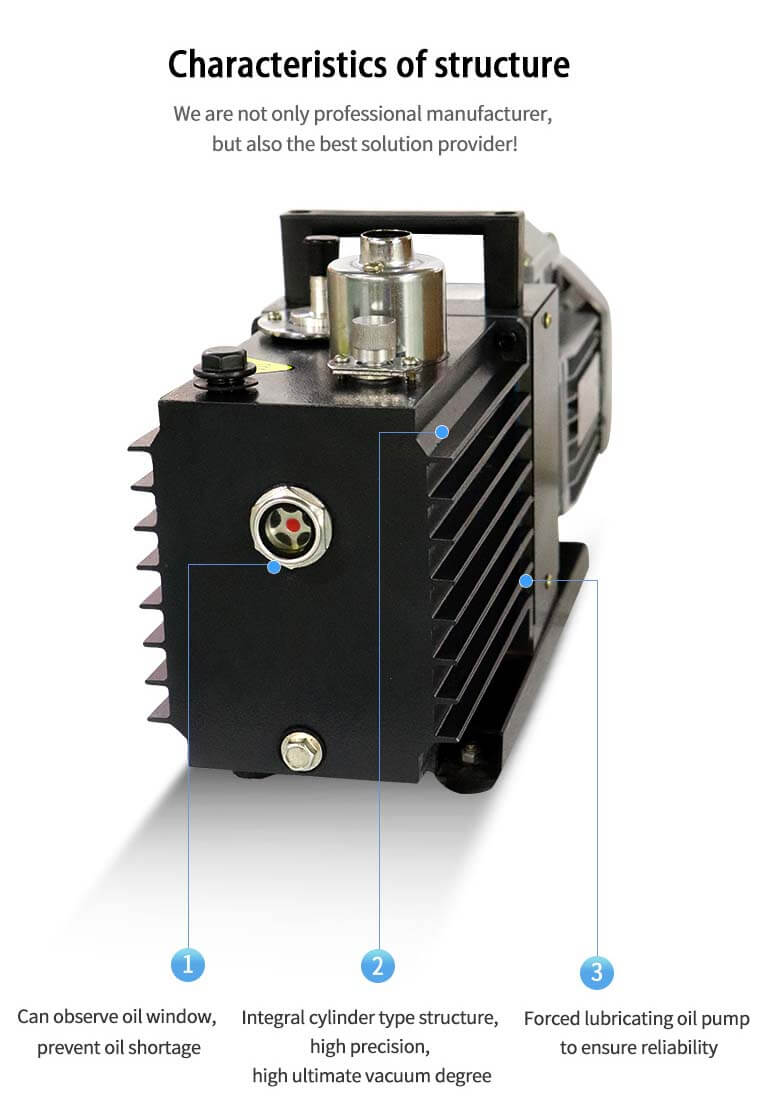

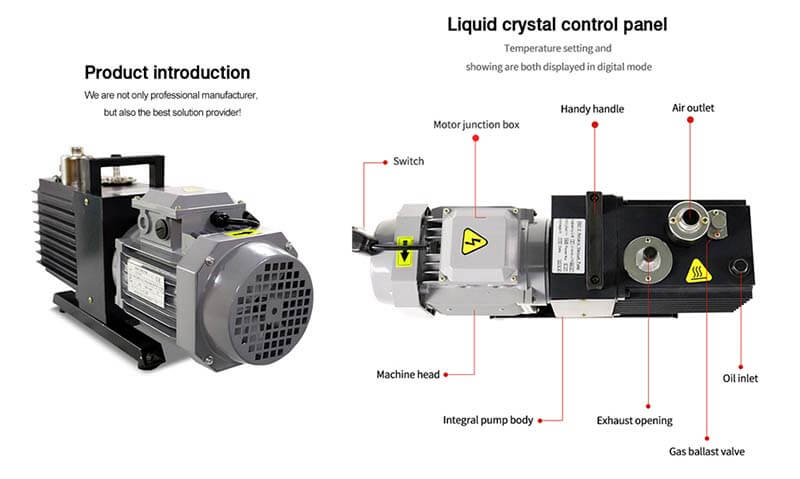

Rotary Vane Vacuum Pump Structure

Rotary vane vacuum pump is mainly composed of pump body, rotor, rotary vane, end cover, spring, etc. A rotor is eccentrically installed in the cavity of the rotary vane vacuum pump. The outer circle of the rotor is tangent to the inner surface of the pump cavity (there is a small gap between the two), and two rotary vanes with springs are installed in the rotor groove. During rotation, the top of the rotary vane is kept in contact with the inner wall of the pump chamber by centrifugal force and the tension of the spring, and the rotor rotates to drive the rotary vane to slide along the inner wall of the pump chamber.

The rotary vane vacuum pump is a positive displacement pump. The gas is sucked in and compressed by the rotary vane in the pump chamber and discharged through the exhaust port. The pump is mainly composed of stator, rotor, rotary vane, etc. The rotor is eccentrically installed into the stator cavity. There are two rotary vanes in the rotor slot, and the rotary vane spring is placed between the two rotary vanes. The inlet and exhaust ports on the stator are separated into two parts by the rotor and the rotor.

When the rotor rotates in the stator cavity, under the combined action of the spring tension and its own centrifugal force, the end of the rotary vane slides against the inner wall of the pump cavity, periodically expanding the cavity volume on the air inlet side and inhaling gas. Gradually reduce the volume of the exhaust port, compress the inhaled gas, and then discharge it from the exhaust port to achieve the purpose of pumping.

The rotary vane vacuum pump is a double-stage direct-connected structure. Its working performance is composed of two parts: a high-pressure stage and a low-pressure stage. Its suction port is connected to the vacuum equipment. During operation, a large amount of gas in the container is sucked and discharged. When the equipment obtains a vacuum, the high-pressure stage exhaust valve is closed, and the gas at the high-pressure stage inlet will be transferred to the second stage, and the suction and discharge of the vacuum equipment through the second stage can be obtained. A certain vacuum, the pump is connected to the motor, the high speed, the small appearance, the compact structure, and the fluidity are convenient to work. Instrument matching, etc. Because it has the advantages of small size, light weight and low operating noise, it is more suitable for use in the laboratory.

Application of Rotary Vane Vacuum Pump

1. It is suitable for vacuuming the closed system. Such as vacuum packaging, vacuum forming, vacuum suction.

2. Inlet pressure range: oil mist will be generated at the exhaust port of the vacuum pump when it is working beyond this range. The working environment temperature and the suction gas temperature should be between 5°C and 40°C.

3. Water or other liquids cannot be removed. Explosive, flammable, high oxygen content and corrosive gases cannot be removed.

4. The motors generally supplied are not explosion-proof. If explosion-proof or other special requirements are required, the motors must meet relevant standards.

Rotary Vane Vacuum Pump Maintenance

1. The pump and surrounding environment should always be kept clean to prevent debris from entering the pump.

2. During the operation of the pump, the amount of pump oil in the oil tank shall not be lower than the center of the oil mark.

3. Different types and grades of vacuum pump oils cannot be mixed.

4. When the pump is in use, due to special accidents such as system damage, when the air inlet is suddenly exposed to the atmosphere, the pump should be stopped as soon as possible, and the pipeline connected to the system should be cut off to prevent fuel injection and pollution of the site.

5. When the pump is stored or used improperly, moisture or other volatile substances enter the pump and affect the ultimate vacuum, open the gas ballast valve to purify it. When the pump oil is contaminated by mechanical impurities or chemical impurities, the pump oil should be replaced.

6. When the pump is not in use, plug the inlet and exhaust ports with rubber caps to prevent dirt from falling into the pump.

7. If the pump is contaminated during operation, it must be disassembled and cleaned.

FBL Machinery Instrument Equipment Co., Ltd. is a comprehensive manufacturer specializing in R&D, production, sales, laboratory, and biochemical pharmaceutical equipment, especially rotary evaporators, glass reactors, vacuum drying ovens, etc. 13 years of production and export experience and a series of ISO9001 and CE certificates, with warehouses in the United States, Spain and Thailand.

If you want to know about our products, or want to buy our equipment, please feel free to contact us, FBL will provide you with the best price for rotary vane vacuum pumps.