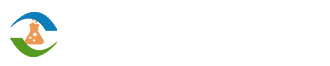

Jacketed kettle is a specialized cooking vessel commonly used in commercial kitchens, food processing plants, and industrial settings. It features a double-walled design, consisting of an inner kettle or cooking chamber and an outer jacket. The space between these two walls is filled with a heating medium, typically steam or hot water.

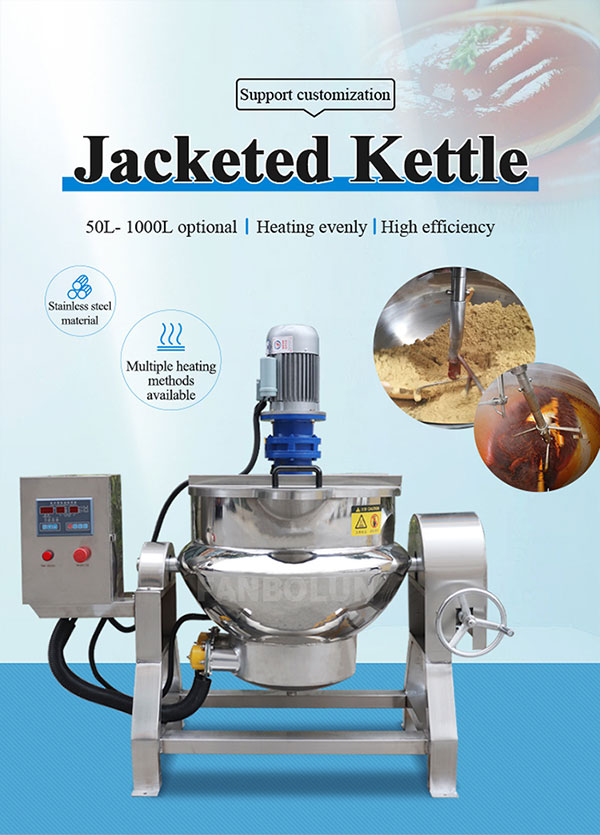

Models of our jacketed kettle

᛫ Electric heating jacketed kettle

᛫ Steam heating jacketed kettle

᛫ Gas heating jacketed kettle

Benefits of jacketed kettle

Even Heating: the double-walled design with an outer jacket filled with a heating medium ensures even distribution of heat throughout the cooking chamber.

Precise Temperature Control: Jacketed kettles equipped with temperature control features, allowing for precise control over the cooking process.

Versatility: Jacketed kettles are versatile and can be used for various cooking applications.

High Production Capacity: available in different sizes, including large-capacity models, making them well-suited for high-volume cooking in commercial settings.

Durability and Hygiene: corrosion resistance, and ease of cleaning.

Application of jacketed kettle

᛫ Soup Production

᛫ Sauce and Gravy Making

᛫ Stewing and Braising

᛫ Jam and Jelly Production

᛫ Confectionery and Candy Making

᛫ Vegetable Blanching

᛫ Dairy Product Processing

᛫ Large-Scale Cooking in Institutions

᛫ Pharmaceutical and Chemical Processing

᛫ Hot Beverage Production

᛫ Canning and Batch Cooking

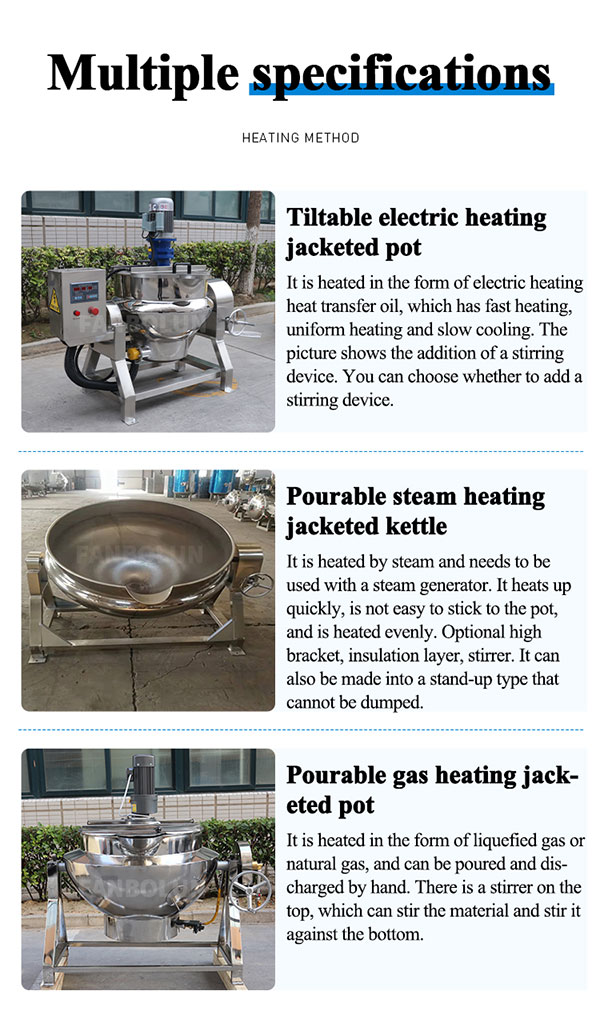

Warehouse in USA | Canada | Spain | Thailand

We have warehouses in the United States (Los Angeles), Canada (Vancouver), Spain (Valencia), Thailand (Bangkok), and have a large inventory,no matter which country you are in, you are guaranteed to receive the goods as quickly as possible.

Why choose us?

᛫ Jacketed kettles now in stock with fast delivery.

᛫ With 13 years of experience in R&D and production of spray dryers.

᛫ Provide you with premium quality products and perfect after-sales service.

᛫ Premium quality with CE certification.

᛫ Factory direct sales with competitive price.

Parameter

Volume(L) | Motor power (kw) | Diameter (mm) | Weight (kg) | Supply voltage (v) | Material | Dimensions (mm) |

50 | 0.75 | 600*420 | 110 | 380V(220V) | 304 | 1200*850*1200 |

100 | 0.75 | 700*470 | 125 | 380V(220V) | 304 | 1300*950*1250 |

200 | 1.5 | 800*550 | 150 | 380V(220V) | 304 | 1450*1050*1350 |

300 | 1.5 | 900*600 | 175 | 380V(220V) | 304 | 1550*1150*1450 |

400 | 1.5 | 1000*680 | 200 | 380V(220V) | 304 | 1650*1250*1550 |

500 | 2.2 | 1100*720 | 225 | 380V(220V) | 304 | 1750*1350*1750 |

600 | 2.2 | 1200*780 | 250 | 380V(220V) | 304 | 1850*1450*1850 |

800 | 2.2 | 1300*870 | 300 | 380V | 304 | 1950*1550*2000 |

1000 | 2.2 | 1400*950 | 350 | 380V | 304 | 2050*1650*2100 |

Volume(L) | Motor power (kw) | Supply voltage (v) | Material |

50 | 0.75 | 380V(220V) | 304 |

100 | 0.75 | 380V(220V) | 304 |

200 | 1.5 | 380V(220V) | 304 |

300 | 1.5 | 380V(220V) | 304 |

400 | 1.5 | 380V(220V) | 304 |

500 | 2.2 | 380V(220V) | 304 |

600 | 2.2 | 380V(220V) | 304 |

800 | 2.2 | 380V | 304 |

1000 | 2.2 | 380V | 304 |