Stainless steel mixing tank with agitator is a common piece of equipment used in various industries, including food and beverage, pharmaceuticals, chemicals, and cosmetics. It's designed for blending, mixing, and homogenizing liquids and sometimes even viscous materials.

Features of our stainless steel mixing tank

* Upper Cover

The top head of the mixing tank can be provided with feed inlet and visual window according to customer requirements.

* Stainless Steel

Made of high quality stainless steel with good ductility not easy to deform,durable and easy to clean.

* Seamless welding

The overall seamless welding,good sealing,not easy to fouling,long service life.

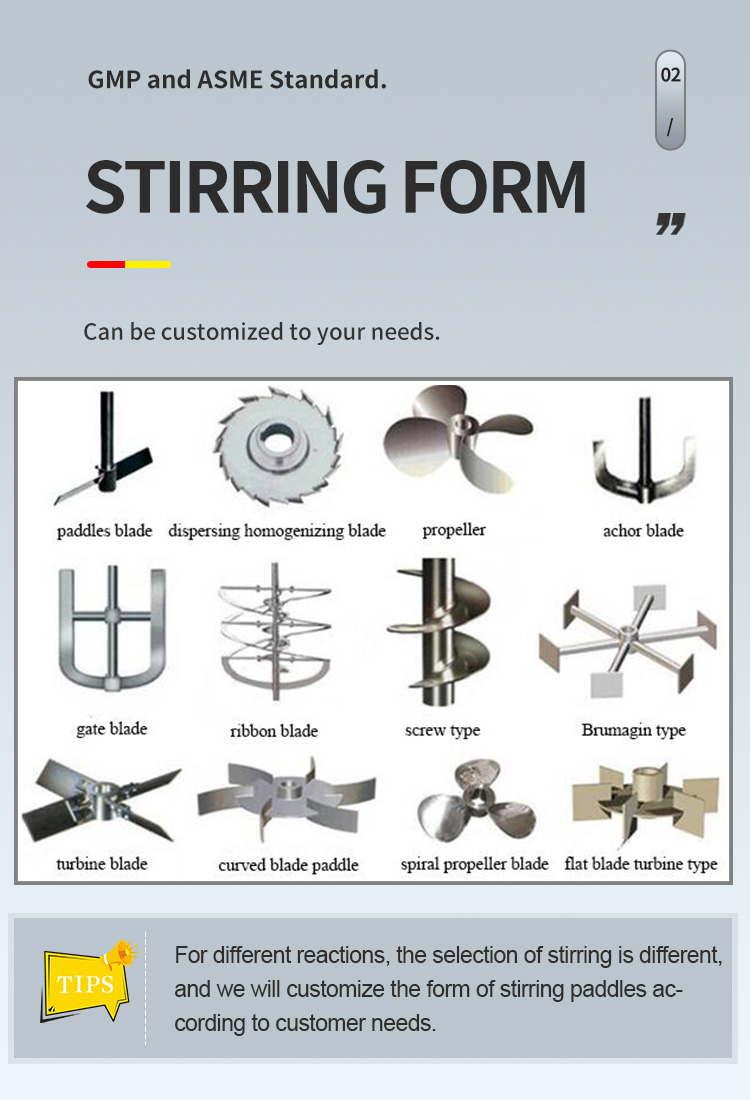

* Stirring panddle

Stainless steel thickened material,strong and durable.

Advantages of our stainless steel mixing tank

* Thickened Material

* Precise Temperature Control

* Low Noise

* Simple Operation

* A variety of specifications

* Support Customization

Application of stainless steel mixing tank

Food and Beverage Industry

Food Processing: Used for mixing ingredients, making sauces, dressings, and soups, and blending food products like yogurt, ice cream, and chocolate.

Beverage Production: Essential for mixing and blending beverage ingredients, such as juices, soft drinks, and alcoholic beverages.

Dairy Industry: Utilized for pasteurization, fermentation, and homogenization of dairy products like milk and cheese.

Pharmaceutical and Biotechnology

Drug Manufacturing: Used for blending and dissolving active pharmaceutical ingredients in solutions, suspensions, and creams.

Bioprocessing: Applied for the mixing of cell cultures, fermentation processes, and the production of biopharmaceuticals.

Chemical Industry

Chemical Processing: Used for mixing, blending, and reacting various chemical compounds in the production of chemicals, dyes, and paints.

Petrochemicals: Utilized for mixing and blending raw materials in the production of petroleum-based products.

Cosmetics and Personal Care

Cosmetic Manufacturing: Essential for mixing and blending ingredients to create cosmetics and personal care products like creams, lotions, shampoos, and perfumes.

Adhesives and Sealants

Manufacturing: Used for homogenizing and blending adhesive and sealant components to ensure consistent quality and performance.

Water and Wastewater Treatment

Treatment Processes: Applied for mixing and agitating chemicals, coagulants, and flocculants in water and wastewater treatment to facilitate chemical reactions and the removal of contaminants.

Paint and Coatings

Paint Manufacturing: Essential for mixing pigments, solvents, and additives in the production of paints and coatings.

Mining and Minerals Processing

Ore Processing: Used for agitating and mixing ore slurry and chemicals in processes like leaching, flotation, and separation.

Oil and Gas Industry

Refining: Applied for blending and mixing various components in the refining process.

Chemical Research and Laboratories

Laboratory Experiments: Used for conducting experiments and research that require controlled mixing and agitation.

Environmental Applications

Environmental Remediation: Used for mixing and agitating remediation materials in soil and groundwater cleanup processes.

Wastewater Treatment

Sludge Treatment: Utilized for the mixing of chemicals and sludge in the treatment of wastewater.

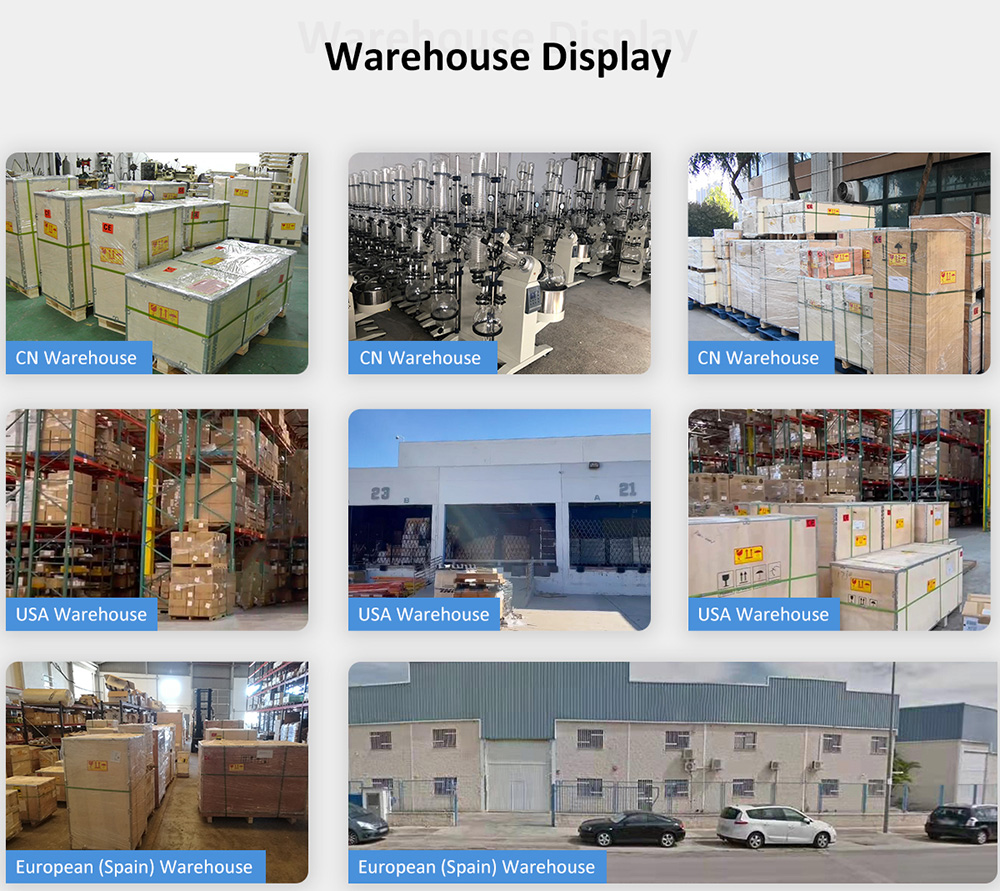

Warehouse in USA | Canada | Spain | Thailand

We have warehouses in the United States (Los Angeles), Canada (Vancouver), Spain (Valencia), Thailand (Bangkok), and have a large inventory,no matter which country you are in, you are guaranteed to receive the goods as quickly as possible.

Why choose us?

1)Stainless steel mixing tank with agitator now in stock with fast delivery.

2) With 13 years of experience in R&D and production of rotary evaporators.

3) provide you with premium quality products and perfect after-sales service.

4) Premium quality with CE certification.

5) Factory direct sales with competitive price.

6) Provide one-stop Extraction Turnkey Solution.

Parameter

Model | Motor power(kw) | Material | Tank structure | Dimension of tank (mm) | Agitator speed(r/min) |

FBL-ST-100 | 0.55 | 304/316L | Single/Multilayer | Φ500*h500*t3 | 0-80 |

FBL-ST-200 | 0.75 | 304/316L | Single/Multilayer | Φ600*h600*t3 | 0-80 |

FBL-ST-300 | 0.75 | 304/316L | Single/Multilayer | Φ750*h600*t3 | 0-80 |

FBL-ST-500 | 1.5 | 304/316L | Single/Multilayer | Φ900*h750*t3 | 0-80 |

FBL-ST-1000 | 2.2 | 304/316L | Single/Multilayer | Φ1000*h1200*t3 | 0-80 |

FBL-ST-2000 | 4.0 | 304/316L | Single/Multilayer | Φ1250*h1500*t3 | 0-80 |

FBL-ST-3000 | 5.5 | 304/316L | Single/Multilayer | Φ1500*h1500*t3 | 0-80 |

FBL-ST-5000 | 7.5 | 304/316L | Single/Multilayer | Φ1800*h1800*t4 | 0-80 |

FBL-ST-10000 | 11 | 304/316L | Single/Multilayer | Φ2000*h3000*t4 | 0-80 |

Model | Motor power(kw) | Material | Agitator speed(r/min) |

FBL-ST-100 | 0.55 | 304/316L | 0-80 |

FBL-ST-200 | 0.75 | 304/316L | 0-80 |

FBL-ST-300 | 0.75 | 304/316L | 0-80 |

FBL-ST-500 | 1.5 | 304/316L | 0-80 |

FBL-ST-1000 | 2.2 | 304/316L | 0-80 |

FBL-ST-2000 | 4.0 | 304/316L | 0-80 |

FBL-ST-3000 | 5.5 | 304/316L | 0-80 |

FBL-ST-5000 | 7.5 | 304/316L | 0-80 |

FBL-ST-10000 | 11 | 304/316L | 0-80 |