Vacuum emulsifying mixer machine is a specialized piece of equipment used in various industries, including the pharmaceutical, cosmetic, and food industries, for the preparation of emulsions, dispersions, and other products that require mixing and homogenization. The vacuum feature is an essential component of this equipment, as it allows for precise control over the emulsification process while minimizing air entrapment and improving product quality.

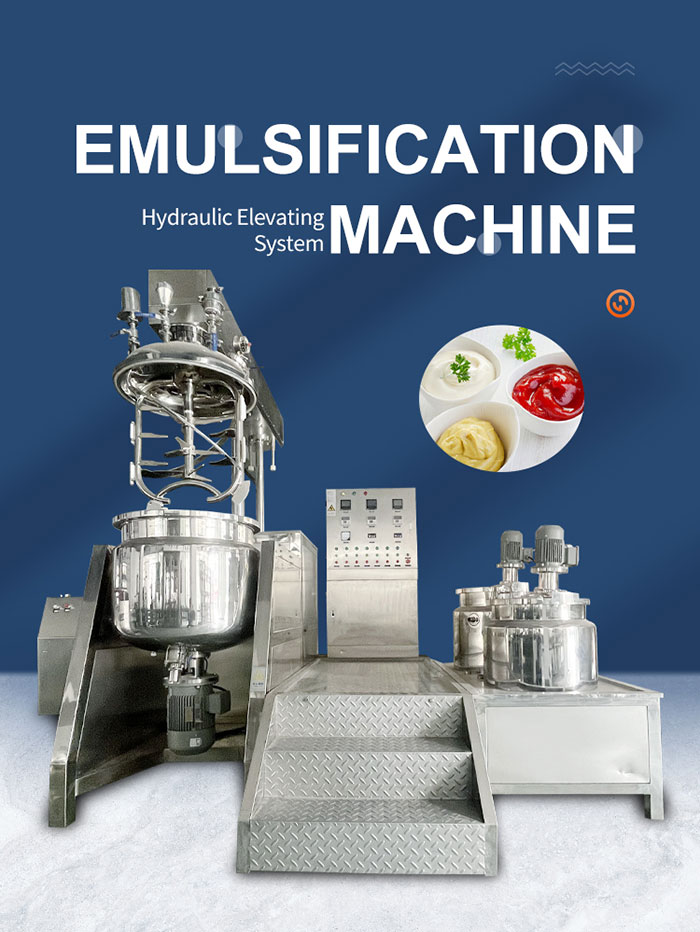

Main components of vacuum emulsifying mixer machine

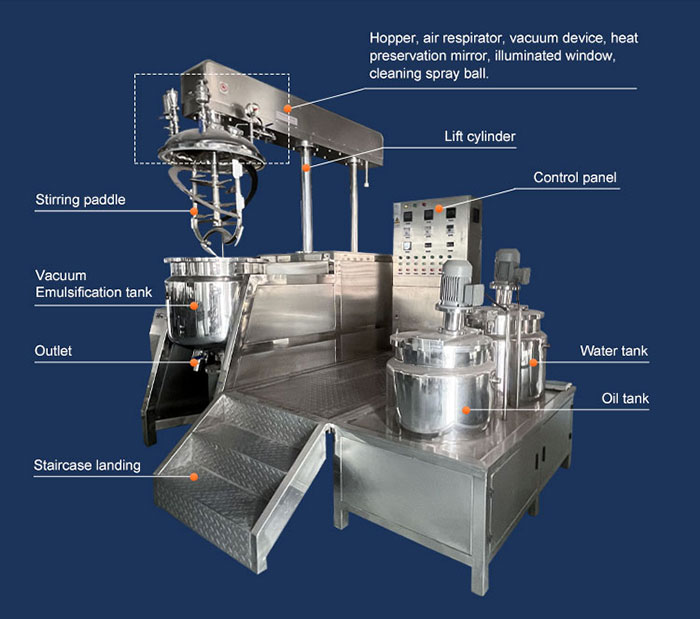

● Stirring paddle

● Vacuum emulsification tank

● Oil tank

● Water tank

● Control panel

● Staircase landing

Applicaiton of vacuum emulsifying mixer machine

Cosmetics and Personal Care Products:

Creams : For the production of facial creams, body lotions, and moisturizers.

Lotions and Serums : Emulsification of skincare products such as lotions and serums.

Makeup Products : Production of foundations, lipsticks, and eyeshadows.

Shampoos and Conditioners : Mixing and emulsification of hair care products.

Pharmaceuticals and Medical Products:

Ointments and Creams : Preparation of pharmaceutical creams and ointments.

Suspensions : Homogenization of pharmaceutical suspensions for oral or topical use.

Vaccines : Emulsification and homogenization of vaccine components.

Dental Products : Mixing and emulsification of dental materials.

Food and Beverage:

Sauces and Dressings : For the production of salad dressings, mayonnaise, and sauces.

Dairy Products : Preparation of yogurt, cheese, and other dairy-based products.

Confectionery : Mixing and emulsification of chocolate, candy, and confectionery products.

Beverages : Production of beverages, including smoothies and nutritional drinks.

Chemicals and Petrochemicals:

Paints and Coatings : Mixing and emulsification of paint and coating formulations.

Adhesives : Preparation of adhesive compounds and sealants.

Specialty Chemicals : Production of various chemical compounds and specialty products.

Petroleum Industry : Emulsification of oil-water mixtures for specific processes.

Biotechnology and Life Sciences:

Cell Culture Media : Preparation of nutrient-rich media for cell culture.

Drug Formulations : Emulsification and homogenization of drug formulations.

Biopharmaceuticals : Production of biopharmaceutical products, including vaccines and biologics.

Research and Development:

Laboratory-scale Emulsification : Used in laboratories for research, experimentation, and product development.

Prototype Formulations : Creating prototype formulations for new product development.

Parameter

Model | Effective Capacity (L) | Emulsify (kw) | Emulsify (r/min) | Agitator (kw) | Agitator (r/min) | Outside Dimension L*W*H (mm) | Outside Dimension Maxh (mm) | Electric heating Power(kw) | Steam heating Power(kw) |

D-20 | 20 | 0.75 | 0~3000 | 0.37 | 0~40 | 1800*1600*1850 | 2700 | 9 | 3 |

D-50 | 50 | 2.2 | 0~3000 | 0.37 | 0~40 | 2700*2000*2015 | 2700 | 25 | 5 |

D-100 | 100 | 3 | 0~3000 | 1.5 | 0~40 | 2920*2120*2200 | 3000 | 27 | 9 |

D-150 | 150 | 3 | 0~3000 | 1.5 | 0~40 | 3110*2120*2200 | 3100 | 27 | 9 |

D-200 | 200 | 4 | 0~3000 | 1.5 | 0~40 | 3150*2200*2200 | 3100 | 40 | 12 |

D-350 | 350 | 4 | 0~3000 | 2.2 | 0~40 | 3650*2650*2550 | 3600 | 50 | 16 |

D-500 | 500 | 5.5 | 0~3000 | 2.2 | 0~40 | 3970*2800*2700 | 3950 | 50 | 16 |

D-1000 | 1000 | 11 | 0~3000 | 4 | 0~40 | 3900*3400*3150 | 4550 | 100 | 30 |

D-2000 | 2000 | 15 | 0~3000 | 7.5 | 0~40 | 4850*4300*3600 | No lift | 120 | 50 |

Model | Effective Capacity (L) | Emulsify (kw) | Emulsify (r/min) | Agitator (kw) | Agitator (r/min) |

D-20 | 20 | 0.75 | 0~3000 | 0.37 | 0~40 |

D-50 | 50 | 2.2 | 0~3000 | 0.37 | 0~40 |

D-100 | 100 | 3 | 0~3000 | 1.5 | 0~40 |

D-150 | 150 | 3 | 0~3000 | 1.5 | 0~40 |

D-200 | 200 | 4 | 0~3000 | 1.5 | 0~40 |

D-350 | 350 | 4 | 0~3000 | 2.2 | 0~40 |

D-500 | 500 | 5.5 | 0~3000 | 2.2 | 0~40 |

D-1000 | 1000 | 11 | 0~3000 | 4 | 0~40 |

D-2000 | 2000 | 15 | 0~3000 | 7.5 | 0~40 |