When we need a 100L glass reactor, how do we choose?

At present, there are various glass reaction equipments on the market, but the glass reaction kettles with a volume of 100L that can meet our needs are only single-layer glass reaction kettles, jacketed glass reaction kettles and stainless steel reaction kettles. This article mainly introduces glass reactors, if you want to know about stainless steel reactors, please click on stainless steel reactors. So, when we need a 100L glass reactor, how should we choose?

100 liter Single-layer glass reactor VS 100 liter Jacketed glass reactor

First of all, it is necessary to determine the environment and requirements required for the experiment to ensure that the selected glass reactor can perfectly achieve the purpose of the experiment. Secondly, consider the price of the glass reactor and choose the appropriate glass reactor.

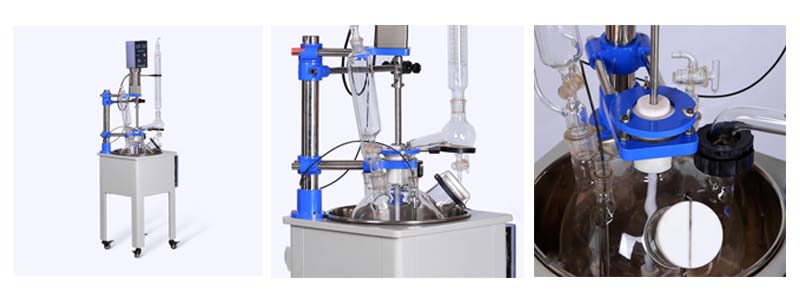

100 Liter Single-Layer Glass Reactor

The single-layer glass reactor can complete high temperature, low temperature, vacuum and other reaction experiments at the same time. The operation is simple, the reaction process is clear at a glance, and it is convenient to control the reaction process. It is an ideal test and production equipment for modern synthetic chemicals, biopharmaceuticals and new materials.

100 Liter Single-Layer Glass Reactor Structure

Features of single-layer glass reactor

1. Sealed PTFE material has strong sealing, anti-corrosion and wear resistance.

2. Stepless speed regulation, stable operation.

3. Clearly display the control and data information plane, the speed is obvious, and it is equipped with an intelligent temperature sensor, which can digitally display the temperature.

6. Large-diameter discharge valve and cleaning port can put solid and liquid materials, and it is easy to clean.

7. Double return, integrated standard port condenser.

8. The main body adopts stainless steel and aluminum alloy structure.

9, stable operation, beautiful appearance, durable.

100 Liter Jacketed Glass Ractor

The jacketed glass reactor is designed with jacketed glass, and the inner layer is equipped with a reaction solvent, which can be used for stirring reaction. reaction. The jacketed glass reaction kettle can be stirred and reacted under normal pressure or negative pressure according to the requirements in the closed glass reaction kettle under the set constant temperature, and can do the reflux and distillation of the reaction solution. The jacketed glass reaction kettle is a Ideal equipment for modern chemical, biopharmaceutical and new material synthesis.

100 Liter Jacketed Glass Reactor Structure

jacketed glass eactors are based on multifunctional reactors. And after years of improvement, the jacketed glass reaction kettle has realized the convenience of high and low temperature control, rapid heating, cooling requirements in the experimental process, and requirements of modern laboratories, chemistry, and pharmaceuticals.

Features of jacketed glass reactor:

1. It is sealed with PTFE material and special rubber compound sealing ring, and the sealing performance is excellent.

2. Condenser to ensure high recovery rate.

3. Standardized connection method, easy to disassemble.

4. Equipped with a discharge switch, the recovery of the solvent is fast.

5. Equipped with a vacuum gauge, you can choose the working vacuum degree.

6. The whole machine is made of stainless steel, aluminum alloy and new synthetic materials, which are anti-corrosion, anti-rust and resistant to various solvents.

As far as the difference is concerned, the body of the jacketed glass reactor produced by FBL instrument is divided into two layers, and the middle part of the outer layer and the inner layer is called the interlayer. The heating of the jacketed glass reactor is completely accomplished through the interlayer.

In summary, if the test requirements require multi-stage temperature control requirements, choose a jacketed glass reactor. If there are no special requirements, choose a single-layer reactor. After understanding these, I believe we can better choose the glass reactor.

After introducing how to choose a suitable glass reactor, how to maintain the glass reactor?

Maintenance of glass reactor:

1. Before using the glass reactor, read the instructions carefully and check the instrument: check whether the glass reactor is damaged or not, and handle it with care.

2. The interface of the glass reactor should not be tightened too tightly, and it should be checked regularly for looseness.

3. Turn on the power switch, and let the machine run from slow to fast. When the machine is stopped, make the machine stop, and then turn off the switch.

4. Clean the sealing ring regularly.

5. The electrical part should not enter the water, and it is strictly forbidden to get wet.

6. It is strictly forbidden for the reactor to work under the condition of overpressure and overtemperature.

7. After use, the oil and stains left on the surface of the machine must be wiped off with a soft cloth to keep it clean.

FBL Machinery Instrument Equipment Co., Ltd. is a comprehensive manufacturer specializing in R&D, production, sales, laboratory, and biochemical pharmaceutical equipment, especially extraction equipment, reaction equipment, drying equipment, etc. 13 years of production and export experience and a series of ISO9001 and CE certificates, with warehouses in the United States, Spain and Thailand.

The glass reactors produced by FBL include 1L, 2L, 3L, 5L, 10L, 20L, 30L, 50L, 100L. In addition, our products also include laboratory equipment such as stainless steel reactors, crystallization reactors and hydrothermal synthesis reactors.

If you want to know about our products, or want to buy our equipment, please feel free to contact us, FBL will provide you with the best price for glass reactors.