Chemical experiments can often bring wonderful visual experience, but the chemical reactions of flammable, explosive and toxic media increase the risk of experiments.

FBL Machinery is a leading laboratory extraction equipment manufacturer, producing extraction equipment, reactor equipment, drying equipment, etc.

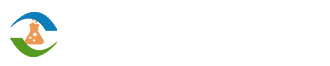

Common reactors include stainless steel reactors, hydrothermal reactors, glass reactors, etc. Among them, the most used and most practical is the stainless steel reactor. The stainless steel reaction kettle is composed of a kettle body, a kettle cover, a jacket, a stirrer, a transmission device, a shaft sealing device, and a support. The materials are generally carbon-manganese steel, stainless steel, zirconium, nickel-based (Hastelloy, Monel) alloys and other composite materials.

Stainless steel reaction kettle has the advantages of rapid heating, high temperature resistance, corrosion resistance, sanitation, no environmental pollution, no need for automatic heating by boiler, and convenient use. And it is widely used in petroleum, chemical, rubber, pesticide, dye, medicine, food and other production users and various scientific research and experimental projects to complete hydrolysis, neutralization, crystallization, distillation, evaporation, storage, hydrogenation, hydrocarbon It is a container for technological processes such as chemistry, polymerization, condensation, heating and mixing, and constant temperature reaction.

Laboratory high pressure reactor equipment manufacturing process:

The laboratory high pressure reaction kettle is composed of two parts: the kettle body and the controller. The kettle body is composed of a stirrer and a transmission system, a cooling device, a reaction vessel, a safety device, and a heating furnace.

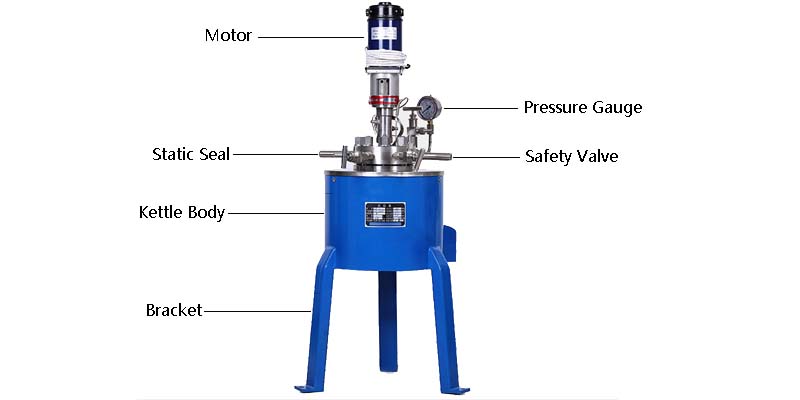

The kettle body and lid of the laboratory high-pressure reactor are made of stainless steel. The kettle body is connected with the flange through threads, and the kettle lid is a normal flat cover, which is fastened and connected by main bolts and nuts that are evenly distributed in the circumferential direction. The main sealing port of the autoclave adopts double-line sealing, and the other sealing points adopt the sealing form of line contact between arc surface and plane, arc surface and arc surface. Relying on the high precision and smoothness of the contact surface, a good sealing effect is achieved.

1. A barrel-shaped silicon carbide furnace core is installed on the outside of the kettle. The electric furnace wire is passed through the furnace core, and its end is pierced from the lower part of the furnace shell side.

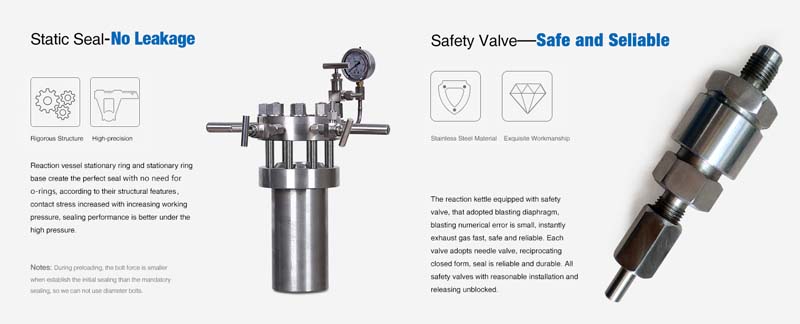

2. The lid of the kettle is equipped with a pressure gauge, a bursting membrane safety device, a vapor-liquid phase valve, a temperature sensor, etc., which are convenient to know the reaction situation in the kettle at any time, adjust the medium ratio in the kettle, and ensure safe operation.

3. The coupling is mainly composed of a pair of inner and outer magnetic rings with magnetic force, and there is a pressure-bearing spacer in the middle. The agitator is driven by a servo motor through a coupling. The purpose of controlling the stirring speed can be achieved by controlling the speed of the servo motor.

4. The upper part of the spacer is equipped with a speed measuring coil. When the integrated stirrer and the inner magnetic ring rotate, the speed measuring coil will generate an induced electromotive force, which corresponds to the stirring speed. The potential is transmitted to the tachometer to display the stirring speed. Rotating speed.

5. A cooling water jacket is installed between the magnetic coupling and the kettle cover. When the operating temperature is high, cooling water should be passed through, and the magnetic steel temperature is too high to demagnetize.

6. The bearing adopts 304 stainless steel bearing or high-strength electrochemical graphite, which is resistant to wear and tear and has a long maintenance period.

Laboratory high pressure reactor features:

1. Cover the size and volume of the original micro-reactor on the market.

2. The reaction kettle can be opened and opened quickly (quick opening structure)

3. The kettle body is disassembled, and the heating furnace is quickly disassembled

4. Special high temperature resistant magnetic coupling stirrer, no need to pass water at 350℃, convenient and safe.

5. Automatic control: The heat release of the materials in the reactor can automatically control the solenoid valve of the cooling coil to open and let the cooling water cool down and keep the temperature constant.

Precautions for the use of laboratory high pressure reactors

1. Sealing performance

The laboratory autoclave is a precision equipment. The sealing ring adopts the form of conical contact sealing, and the purpose of sealing is achieved by tightening the main bolts to press them against each other. Therefore, special care must be taken for the sealing cone to avoid damage caused by various collisions. When installing the cover, place the reactor body first, then put the cover in a fixed position and install it on the kettle body carefully. When tightening the main bolts, they must be tightened diagonally and symmetrically several times. Evenly, do not allow the kettle cover to tilt to one side to achieve a good sealing effect, and do not exceed the specified tightening torque to prevent the sealing surface from being squeezed or accelerated wear. All threaded connections need to be coated with oil or oil-mixed graphite when assembling. If the sealing surface is damaged, it needs to be reworked and repaired to restore good sealing performance.

2. Sealing operation

The air inlet and exhaust valve are sealed with needle valve. When closing, just turn the valve needle gently and press the cover tightly to achieve a good seal. It is forbidden to use excessive force to avoid damage to the sealing surface.

3. Temperature rise and pressure test

The autoclave should be heated, pressurized and sealed before use. Air and nitrogen can be used as the test medium, but inert gas is best. Oxygen or other flammable and explosive gases are strictly prohibited. The temperature increase and pressure increase must be carried out slowly. The heating rate is not more than 80 degrees/hour. During the pressure test, connect the inlet valve of the autoclave to the compressor (or high-pressure pump) with a connecting pipe. The pressure increase must be carried out in stages, with 20% of the working pressure as the interval, stay for 5 minutes for each liter level, and stay for 30 minutes when the test pressure is raised to check the sealing condition. The test pressure is 100-105% working pressure. If a leak is found, the pressure should be reduced first, and then the nut and joint should be properly tightened. It is strictly forbidden to tighten the nut and joint under high pressure.

4. Cooling process

During the reaction process, rapid cooling and rapid heating are prohibited to prevent excessive temperature stress from causing cracks in the kettle body. After the reaction is over, first cool down, either by water cooling (exothermic reaction) or air cooling, and then release the high-pressure gas in the kettle to reduce the pressure to normal pressure, and then unscrew the bolts symmetrically and evenly. In the process of opening the lid, special attention should be paid to protecting the sealing surface, and the lid of the kettle should be lifted evenly to avoid damage to the sealing ring of the lid and the kettle body due to collision.

5. Follow-up processing

After each operation, the residues on the autoclave body and lid should be removed. All sealing surfaces on the autoclave should be cleaned frequently and kept dry. Hard objects or soft objects with rough surfaces are not allowed to be cleaned.

The laboratory autoclave produced by FBL has stable performance and easy operation. In addition, we also have rotary evaporators, electric heating jackets, and other reactor equipment. 13 years of production and export experience and a series of ISO9001 and CE certificates, with warehouses in the United States, Spain and Thailand.

If you want to know about our products, or want to buy our equipment, please feel free to contact us, FBL will provide you with the best price for laboratory autoclave.